The most important part of the tank truck is the tank body. The aluminum tanker is about 20% lighter than the steel tanker of the same size, but the transportation can be increased by 30%. At the same time, due to the high strength, corrosion resistance and wear resistance of the alloy aluminum plate for tank truck, the aluminum alloy load tanker is of longer service life and higher economic profit.

As an important logistics equipment, the tank truck are widely used in the automobile transportation industry. For tank trucks, the weight of the tank body accounts for a large proportion of the weight of the entire vehicle. Reducing the weight of the tank body has become the focus of many tank truck manufacturers.

At present, there are two kinds of metals for the manufacturing of fuel tankers: carbon steel and aluminum. In the transportation of gasoline, diesel and other oil products, especially for gasoline, the use of carbon steel tanks is easy to rust and needs anti-corrosion improvement, otherwise it will contaminate the oil.

With the continuous improvement of environmental protection and fuel saving and overload control measures for commercial vehicles, people’s acceptance rate of tankers with high configuration is gradually increasing, and the calculation of operating costs is more rational. The light-weight aluminum alloy tank truck with high safety, light weight, and large standard transport loads has been promoted worldwide.

The aluminum sheet for tanker body is not only of light weight, but also high strength. In fact, aluminum alloy has been widely used in aerospace, ships, high-speed rail and other fields that require high strength

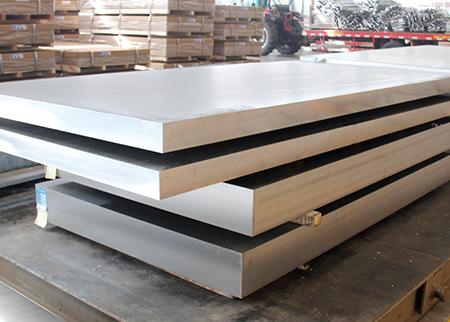

The alloys of aluminum standard plate for tanker

The main alloys of aluminum tanker plates are 5083, 5182, 5454 and 5754. 5083 aluminum plate with magnesium as a main element, has good welding performance, corrosion resistance and processing performance, medium strength, which is often used in the manufacture of liquid tankers such as oil tankers.

5754 medium and thick plate is of medium strength, good corrosion resistance, weldability and easy processing and forming. It is a typical Al-Mg aluminum alloy.

5454 aluminum plate with a thickness range of 0.15-600mm, a width range of 20-2650mm, and a length range of 500-16000mm, meets the diverse needs of different customers. The 5454 tanker aluminum plate has good conductivity and energy absorption performance, which can prevent explosions in the case of accidents.

The 5182 aluminum plate belongs to the Al-Mg alloy, featuring good corrosion resistance, excellent weldability, good cold workability, and medium strength.

The specification of alloy aluminium plate for tank truck

Alloy | Thickness | Width | Length |

5083 | 2.0-8.0 | 1000-2000 | 2000-12600 |

5052 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5754 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5454 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5182 | 4.0-7.0 | 980-2200 | 800-9000 |

The advantages of aluminium wide plate for tankers

1. It helps to realize the lightweight of the car body.

2. The aluminium plates contributes to improve the corrosion resistance of the tank and the life of the truck body.

3. The aluminum tank body is of high recycling rate.

4. It is of good ductility, eliminating some hidden safety hazards.

5. The lightweight of aluminum alloy oil tanker means reduced fuel consumption and pollutant emissions of the car.