3000 Series Alloy Metal Aluminum Coil

Al metal alloy: 3003, 3005, 3105 etc

Alu temper: O - H112, T3 - T8, T351 - T851

Width: 200mm - 2650mm

Thickness: 0.2mm - 8mm

Technology: hot rolled ( DC ), cold rolling ( CC ), cast

Standard: ASTM B209, GB/T 3880, EN AW etc

Technology: hot rolled ( DC ), cold rolling ( CC ), cast

Standard: ASTM B209, GB/T 3880, EN AW, DIN, MSRR, AMS, JIS, AISI, BS, etc

Custom service: acceptable ( OEM, ODM, etc )

3000 series alloys

3003 aluminum coil, 3004 aluminum coil, 3005 aluminum coil, 3104 aluminum coil, 3105 aluminum coil, etc

Temper

Soft HO, H11, H12, H13, H14, H15, H16, H17, H18, H19, H20, H21, H22, H23, H24, H25, H26, H27, H28, H29, H30, H31, H32, H33, H34, H35, H36, H37, H38, H39, H46, H111, H112, H114, H116, H131, H321 etc

According to the surface treatment, it can be divided into

3000 series alloy metal color aluminum coil

3000 series alloy metal embossed aluminum coil

3000 series alloy metal mirror aluminum coil

3000 series alloy metal anodized aluminum coil

3000 series alloy metal color coated aluminum coil

Al metal alloy:3003 3004 3005 3105 etc

Alu temper: O - H112, T3 - T8, T351 - T851 etc

Width: 25mm - 1300mm

Thickness: 0.3mm - 3mm

Technology: hot rolled ( DC ), cold rolling ( CC ), cast

Standard: ASTM B209, GB/T 3880, EN AW, DIN, MSRR, AMS, JIS, AISI, BS, etc

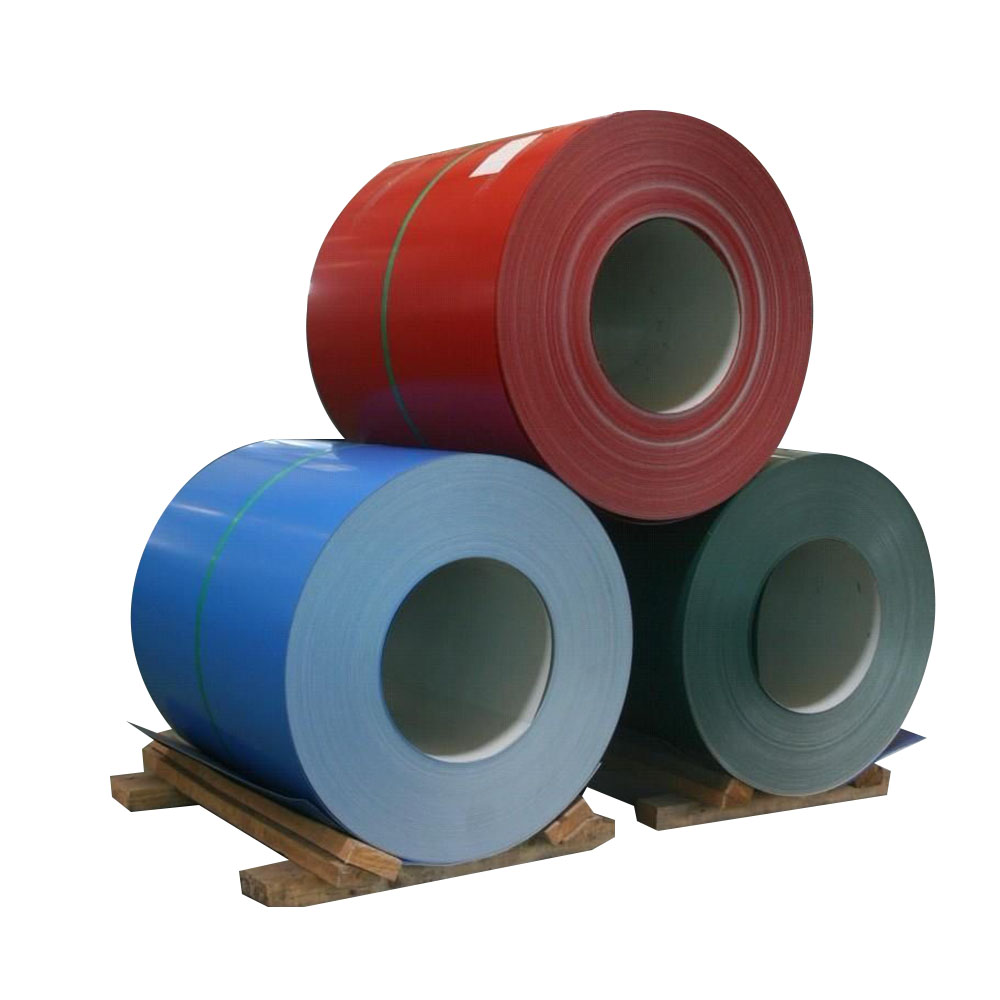

3000 Coated Aluminum Coil | 3003 3004 3005 3105 color Coated Aluminum Coil

3000 series coated aluminum coil provided by APRO includes 3003, 3004, 3105 and 3005 series. The 3003 and 3A21 series are the two representative series.

3000 Coated Aluminum Coil Features This series coated aluminum coil is anticorrosive and its production technology is good.

This series coated aluminum coil provided by includes 3003, 3004, 3105 and 3005 series. The 3003 and 3A21 series are the two representative series.

3000 Coated Aluminum Coil Features

This series coated aluminum coil is anticorrosive and its production technology is good.

The main ingredient in it is manganese element and the content is between 1.0% and 1.5%.

3000 series

Color coated aluminum coil

Thickness:0.3-3mm

Width:25-1300mm

Color coated

3000 Coated Aluminum Coil Applications

As a result of it good property in anti-corrosion, this series coated aluminum coil is commonly used in moist environments like air conditioners, refrigerators, at the bottom of cars, etc.

The products have versatile applications such as for shipping,printing,automobile,domestic appliances,decorating,packaging and other fields. wall panels, curtain wall, gutter boards, roof, roller shutters, column decoration and building renovation, indoor ceiling, elevators, wallboards of highway tunnel, signboards, show stands, bus stops, parks, top cover of gallery, aluminum cellular panels, etc.

Color coated aluminum coil is the aluminum coil as the base material, after the surface paint coloring treatment to get the product, common fluorocarbon coating, polyester coating, etc.. Color coated coil base material is generally used 3004 aluminum coil, 3105 aluminum coil, etc. With the performance advantages of color coated aluminum coil recognized by everyone, its application areas are becoming more and more extensive.

Color coated aluminum coil is a new type of material with good flatness, decorative, weather resistance, mechanical, environmental protection, thus widely used in aluminum composite panels, industrial plant roofing walls, aluminum louvers, composite panels, aluminum ceilings, easy to pull cans, electronic products.

Color coated aluminum coil is chemically coated on the clean substrate surface after removing the antirust oil, rust spots, dust, etc. attached to the surface of the aluminum coil substrate. The product quality of color coated coil depends on the basic properties of the substrate and coating, and also on the production and operation control techniques.

Color coated aluminum coil substrate 3004 aluminum coil / 3105 aluminum coil performance introduction

Color coated aluminum coil with 3004 aluminum coil: 3004 aluminum coil belongs to a series of AL-Mn alloy, with higher strength than 3003 aluminum sheet, good formability, solubility and corrosion resistance, requiring higher strength parts than 3003 alloy.

Color coated aluminum coil with 3105 aluminum coil: 3105 aluminum coil has good rust resistance, good electrical conductivity, high plasticity in the annealed state, plasticity is still good when semi-cold work hardening, low plasticity when cold work hardening, good corrosion resistance, good weldability.

Aluminium coil coating

Coil coating is an industrial process used to produce precoated aluminium coils. There are different types of coatings: anodizing, paint, liquid or powder coating. This method is used to promote the use of aluminium in the most environmental conditions. For this reason application of coil coatings embraces two large industries: building and interior design.

Coil coating process

Coated aluminium can be used in food packaging to manufactures containers and cans. Coated aluminium makes trays more resistant to food with an aggressive pH or high salinity. More than this, it improves the aesthetic appeal of containers, adding personalisation capabilities and enhancing in the consumers the perception of the quality of the product.