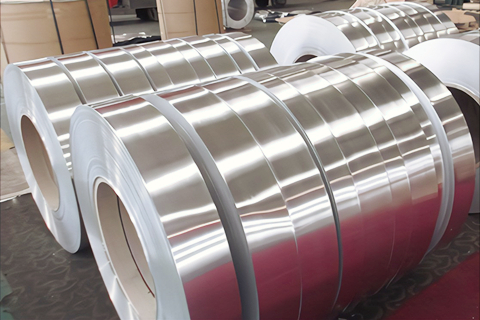

wholesale 3003 3004 3005 3105 aluminum sheet strip Aluminum coil

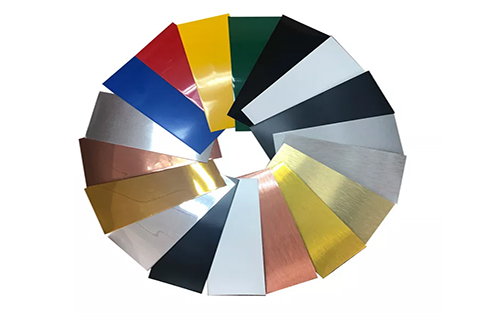

Aluminum & its alloys are today known as one of the most practical of metals for a variety of reasons. Its light-weight, low cost and modern appearance are among the primary reasons for its widespread use. It is non-sparking, electrically conductive, thermally conductive, non-magnetic, chemically resistant and reflective.It is mainly used in the construction, marine and aircraft industries because of its ease of fabrication, non-toxicity, strength (pound-for pound), and resistance to the corrosive atmospheres of industry and marine environments. Anodizing increases this corrosion resistance and also permits iridescent finishes in different colors. Some alloys are slightly corrosive and so are cladded with a thin layer of aluminum for added protection.

Specifications

Equivalent product name

Flexible aluminum strip, slitting aluminum strip, flat aluminum strip, aluminum winding strip, etc

Equivalent alloy name

A1050, 1050a, aa1050, 1050aa, al1050, al1050a, a 1050, aa 1050, jis a1050p, al1050 class, aw1050, en1050 grade etc

Temper

Soft HO (h0), F、O、H12、H14、H16、H18、H22、H24、H26、H28

Applications

1050 aluminum strip coils are widely used in building, packaging, food, air-conditioner and solar energy, curtain/decoration, construction&industry, PS/Printing plate base, framework, cap material, air conditioning, pot container, refrigeration, electrical and electronic products, aluminum billets, aerospace, mold, instrumentation, chemical, construction, packaging, anti-corrosion insulation, air conditioning, solar energy, conductors, hoses, marine accessories., refrigerator industries and other industries.

Other Aluminum strips

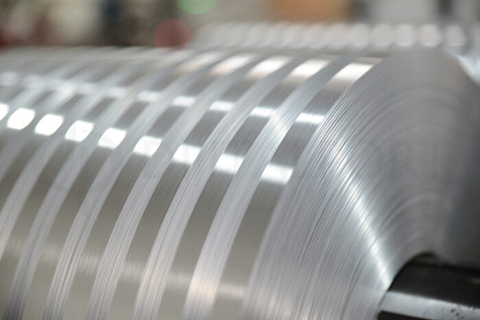

The 1050 aluminum strip belongs to pure aluminum coil series. The aluminum content of the 1050 aluminum is 99.50%,them have high plasticity, corrosion resistance,good conductivity and thermal conductivity,but low strength,no heat treatment to strengthen, poor cutting, acceptable for contact welding, gas welding. According to the international brand naming principle, the aluminum content must reach 99.5% or above for qualified products.Because it does not contain other technical elements, so the production process is relatively simple, the price is relatively cheap, is the most commonly used series in the conventional industry at present.

1060 aluminum strip has the characteristics of flat surface, high cleanliness, suitable for polymer welding, and product

elongation, tensile strength, fully able to meet the conventional processing requirements (punching, drawing) high formability, is widely used in soft batteries Connections, aluminum-plastic panels, lamps, signs, and other fields.