Product Details

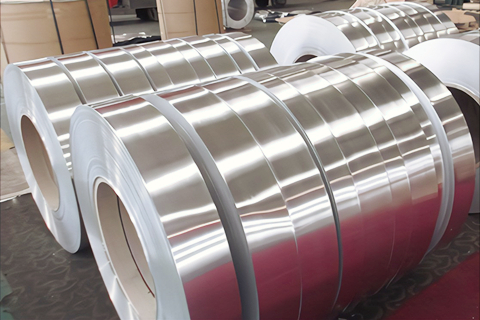

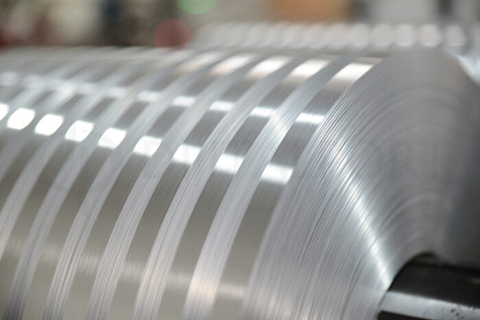

Color Coated Aluminium Strips Channel Letter Aluminum Coils Aluminum Roll Supplier

Aluminum Coil strip Aluminium Strip 10mm - 2500mm Width / 0.1mm - 500mm Thickness Aluminum Alloy Coil

1050 aluminum strip has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength and can be processed well. 1050 aluminum strip cannot be strengthened by heat treatment and has poor mechanical properties, so it can accept contact welding and gas welding. It is a kind of library alloy metal material commonly used in industry.

Specifications

Equivalent product name

Flexible aluminum strip, slitting aluminum strip, flat aluminum strip, aluminum winding strip, etc

Equivalent alloy name

A1050, 1050a, aa1050, 1050aa, al1050, al1050a, a 1050, aa 1050, jis a1050p, al1050 class, aw1050, en1050 grade etc

Temper

Soft HO (h0), F、O、H12、H14、H16、H18、H22、H24、H26、H28

Applications

1050 aluminum strip coils are widely used in building, packaging, food, air-conditioner and solar energy, curtain/decoration, construction&industry, PS/Printing plate base, framework, cap material, air conditioning, pot container, refrigeration, electrical and electronic products, aluminum billets, aerospace, mold, instrumentation, chemical, construction, packaging, anti-corrosion insulation, air conditioning, solar energy, conductors, hoses, marine accessories., refrigerator industries and other industries.

Other Aluminum strips

3003 aluminum strip is AL-Mn alloy, which is the most widely used rust-proof aluminum and can not be strengthened by heat treatment Therefore, it adopts cold processing method to improve its mechanical properties; in the annealed state, it has high plasticity and is semi-cold-hardened When the plasticity is still good, cold work hardening low plasticity, good corrosion resistance, good weldability, poor cutting performance.

The 5052 aluminum strip belongs to the Al-Mg series alloy and has a wide range of applications and is the most promising aluminum alloy Good corrosion resistance, excellent weldability, good cold workability, and moderate strength 5052 alloy aluminum coil has high strength, especially high fatigue strength, high plasticity and corrosion resistance, good weldability, poor cutting performance, and can be polished.

5754 aluminum strip belongs to AL-MG rust-proof aluminum It has the characteristics of moderate strength, good corrosion resistance, weldability, and easy processing and forming It is a typical alloy in Al-Mg alloys The 5754 with different heat treatment conditions is the main material used in automobile manufacturing (car doors, molds, seals) and can making industry productions.

5083 aluminum strip is the most promising alloy, its excellent corrosion resistance makes 5083 aluminum coil widely used in marine applications such as ships, and automotive, aircraft welding parts, subway light rail, etc , as well as pressure vessels that need strict fire prevention (such as liquid tanker, refrigerated trucks, refrigerated containers), refrigeration equipment, television towers, drilling equipment, aluminum for transportation and so on.

6061 aluminum alloy is produced by heat treatment pre-tensile process of high quality aluminum alloy products, with excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, dense material without defects and easy polishing, color film is easy, excellent oxidation effect and other fine characteristics.6063 aluminum alloy is widely used in building aluminum doors and Windows, curtain wall frame, is a common aluminum alloy model.