Color coated aluminum coil

Color Coated Aluminum Coil PE / PVDF Prepainted Aluminium Roll

with Factory Price

This series aluminum coil produced by APRO includes 3003 3004 3005 3104 3105 series etc.

According to the surface treatment, it can be divided into

3000 series alloy metal color aluminum coil

3000 series alloy metal embossed aluminum coil

3000 series alloy metal mirror aluminum coil

3000 series alloy metal anodized aluminum coil

Specifications

Model Numberaluminum coil 3105

TemperH14

MaterialAluminium alloy

Price TermsFOB CIF CFR DAP etc

Technologyhot rolled ( DC ), cold rolling ( CC ), cast

Surface TreatmentPE PVDF Coated etc

Thickness0.381mm-0.533mm

Width25.10mm-76.581mm

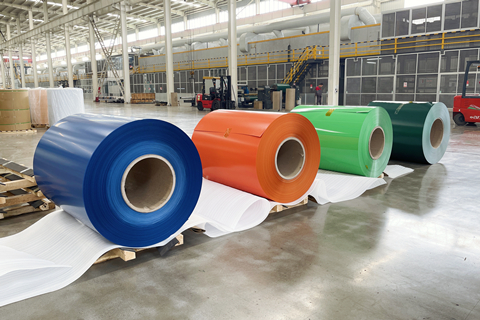

ColorWhite series, metallic series, Dark series, Gold series( accept color customs)

Coating thicknessPVDF Over 25 micron, PE over 20 micron

MOQ3 TONs

Each Coil weight400lbs/each

Customerize sizeSize can be produced as per clients requirement.

ApplicationACP Building,Roofing,Indoor,Outdoor,Truck Panel,Rolling shutter etc.

Al metal alloy1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000 series etc

Alu temperO - H112, T3 - T8, T351 - T851 etc

Thickness0.3mm - 6mm

Width900mm - 1600mm

3105 Aluminum Coil

Prepainted Alloy Color Coated 3000 series Aluminum Coil Stock Suppliers.3105 aluminum coil with 98% pure aluminum and slight alloy additions for strength. 0.3% of copper is added to 3105 aluminum coil, so the conductivity turns out to be 41%. For its contents and processing technologies, 3105 aluminum coil is light in weight and it has semi-smooth surface.

ALUMINUM COIL APPLICATIONOur aluminum coil ailable in alloys in the 1000 to 8000 series range, we stock a full range of aluminum coils to service a wide range of industries, including automotive, pharmaceutical, electrical, and food service. It is important to note that choosing the right alloy for the aluminum coil is directly dependent on the specific use case. Before purchasing any aluminum coils, it is vital you understand the specific strains the material will face during use.

Properties to pay attention to includeTensile Strength, Wettability, Weldability, Formability, Corrosion Resistance