Product Details

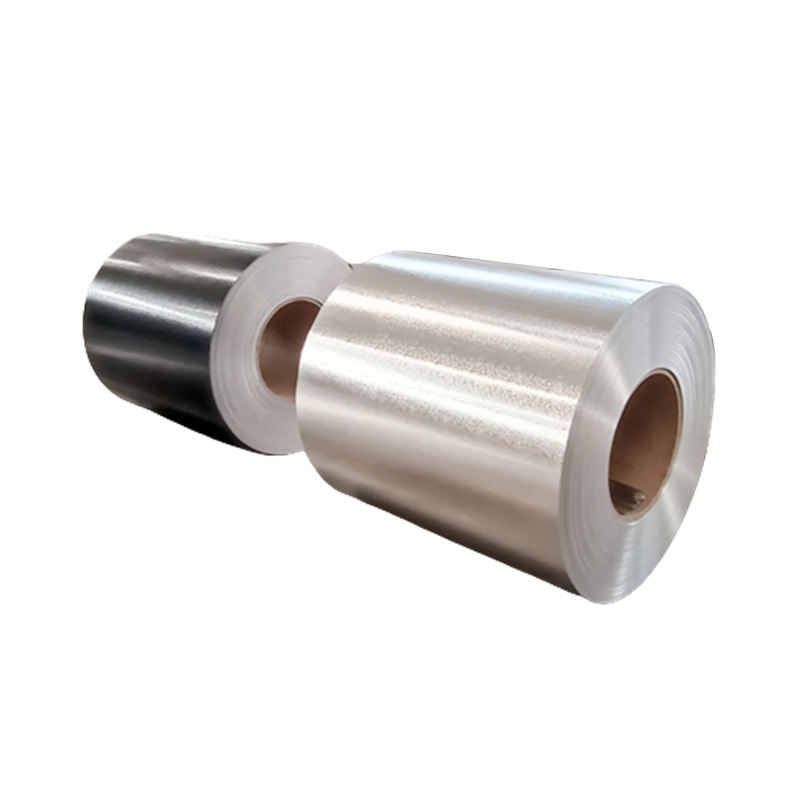

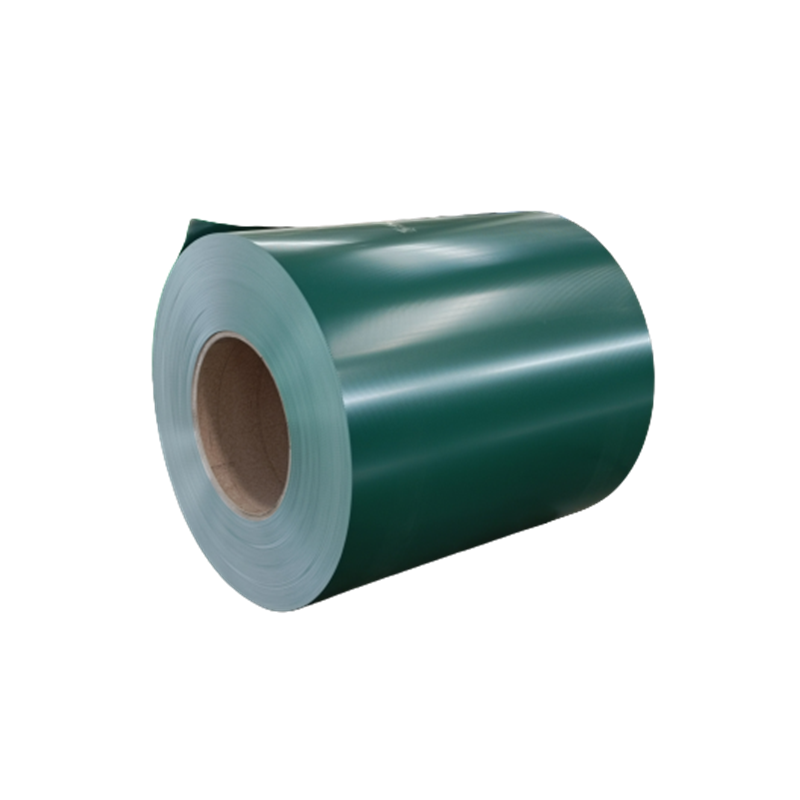

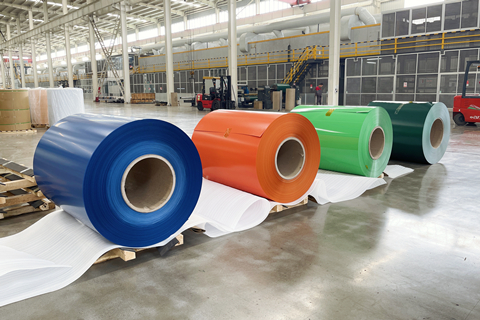

Prepainted Alloy Color Coated Aluminum Coil Stock Suppliers from China

3105 aluminum is a 3000-series aluminum alloy: the main alloying addition is manganese, and it is formulated for primary forming into wrought products. 3105 is the Aluminum Association (AA) designation for this material.

Fabrication and Heat Treatment

l Machinability

Aluminum 3105 alloy has average machinability. However, its machinability can be increased in harder tempers than in annealed condition. Oil lubricant are used for machining this alloy.

l Forming

Aluminum 3105 alloy has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2t range for annealed H12,H14 and H16 tempers. Bend radii of 2 to 7 t should be used for the H18 temper.

l Welding

Aluminum 3105 alloy has good weldability. It can be welded using arc welding method.

l Heat Treatment

Aluminium 3105 alloy does not react to heat treatment expect during cold working.

Application

Color-coated aluminum coils, aluminum-plastic panels, integrated metal insulation panels, aluminum veneers, aluminum honeycomb panels, aluminum ceilings and sheets.

Aluminum metal roof, aluminum corrugated board, interior aluminum plate, exterior aluminum plate, rolling door, downspout, decorative strip.

Aluminum packaging for pipes, traffic signs, aluminum curtain walls, aluminum cooking utensils, solar panels, etc.

Air conditioning foils, condensers, panels, interior panels.

Features

Low density and light weight.

easy to handle, can be strengthened.

Strong plasticity and easy processing.

Strong corrosion resistance.

No low temperature brittleness.

Good electrical and thermal conductivity.

Sound absorption.

Nuclear radiation resistance.

Beautiful, the surface can be reprocessed.